Product overview

Our systems incorporate fully automated water filtration systems that self clean and enable clean water to be supplied to the dust-suppression infrastructure.

All pump modules are constructed from industrial grade components.

They are fully containerised, air conditioned and incorporate dust-proof components to protect them from the harsh operating environment of heavy industry.

Applications

- Stockpiles

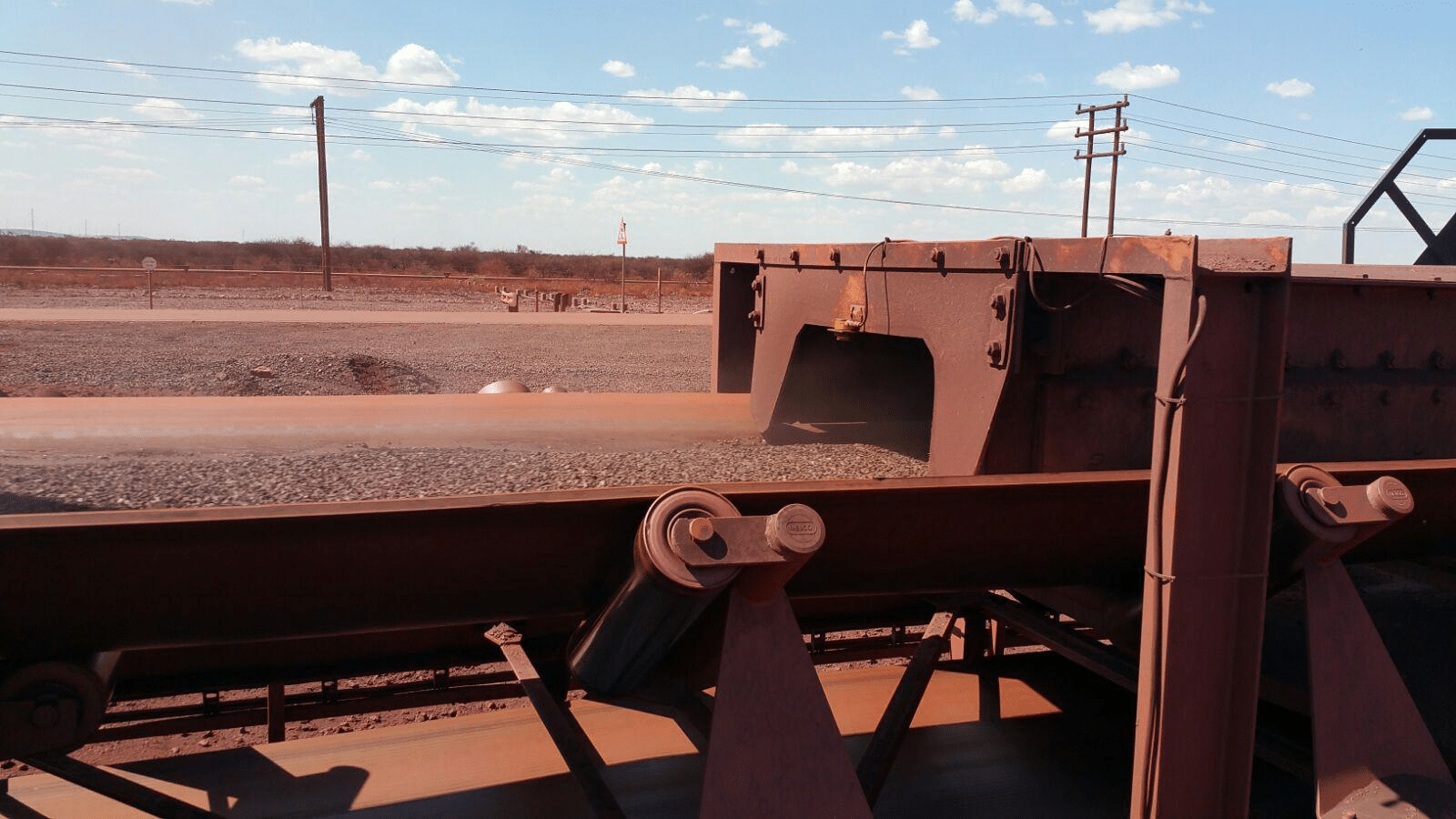

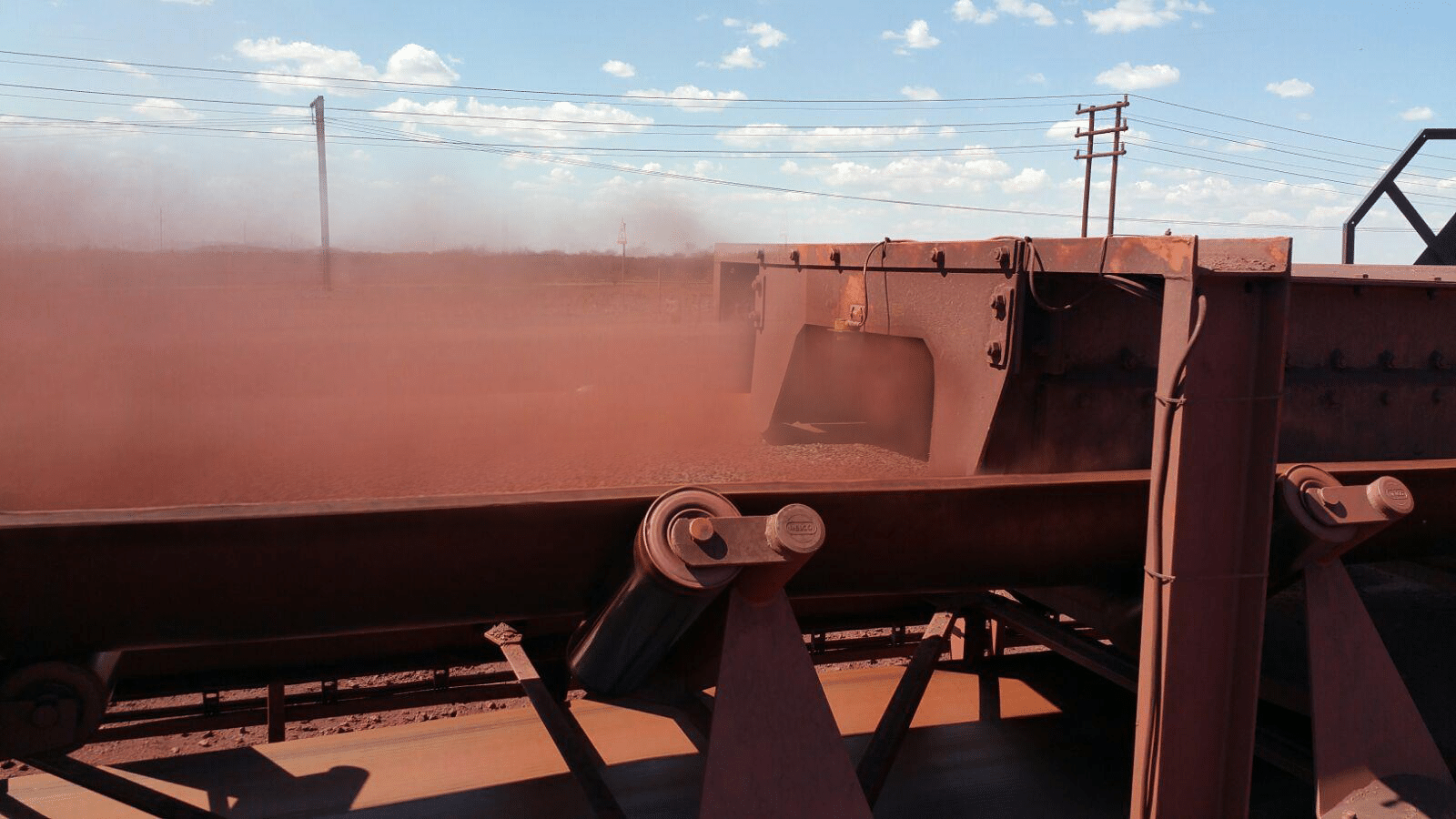

- Conveyors

- Rail wagons

- Transfer points

- Tipping areas

- Loading terminals

- Storage facilities

- Demolition sites

- Excavations

- Quarries

- Rock crushing plant

Key Benefits

- Reduces respirable dust by 80%+ by suppressing airborne dust before it can spread.

- Minimises water usage by atomising water into ultra-fine droplets.

- Eliminates excessive moisture content in material.

- Minimises conveyor slippage and reduces chute blockages.

- Improves housekeeping standards by capturing dust at its source.

- Increases safe work areas during operation by improving visibility and air quality.

- Our systems are purpose-built to meet the unique requirements of each customer and project.

Dust suppression vs dust prevention

There are two main ways to control fugitive dust during material handling processes.

At Dust-A-Side Australia, we utilise advanced high-pressure dust suppression systems (DSS) that use significantly less water while effectively controlling airborne dust. Unlike traditional low-pressure systems, which rely on large volumes of water at close range to wet down dust near the transfer point, our DSS technology applies a fine atomised mist at high pressure (> 50 bar).

This fine mist binds to dust particles already in the air, causing them to settle quickly to the ground, aided by gravity. This method is highly effective for controlling respirable-sized dust particles (typically less than 10 microns), which pose the greatest health risks by lodging in the lower respiratory tract. Left unmanaged, such dust can cause health issues such as vision irritation, pneumoconiosis, or silicosis, depending on the material being handled.

The advantages of high-pressure dust suppression systems extend beyond health and safety:

- Reduced water usage: By atomising water into fine droplets, less water is required compared to low-pressure systems.

- Improved downstream processes: Moisture is added to the air, not directly to the material, reducing the risk of conveyor slippage, chute blockages, or other process interruptions caused by wet materials.

At Dust-A-Side Australia, we provide reliable and efficient dust control solutions tailored to meet the unique requirements of each operation, ensuring maximum effectiveness while minimising resource use.

What are Dust Suppression Systems?

Dust Suppression Systems (DSS) are engineered solutions designed to prevent and control airborne dust in mining, industrial, civil, and agricultural operations. They use a combination of low-pressure spray systems, high-pressure misting, and liquid additives to suppress dust efficiently while minimising water consumption.

How do Dust Suppression Systems work?

DSS solutions function in three primary ways:

- Prevention – Low-pressure water sprays (2-10 bar) pre-wet material to reduce dust generation at transfer points.

- Suppression – High-pressure misting (40+ bar) captures airborne dust particles and brings them back to the surface.

- Enhancement using liquid additives – Surfactants such as HydroWet improve water penetration, while binders such as HydroTac and Aquatarp form protective crusts on stockpiles and haul roads.

What types of Dust Suppression Systems do you offer?

Dust-A-Side Australia provides:

- Fixed suppression systems for conveyors, crushers, tip areas, and stockpiles.

- Fog cannons and misting systems for general airborne dust control.

- Liquid additives such as HydroWet (surfactants) and HydroTac (binders).

Custom-built solutions and systems for specific industry needs.

What are the benefits of using these systems?

- Up to 80% reduction in respirable dust.

- Significant water savings through optimised application.

- Prevention of excessive moisture content in materials.

- Reduced conveyor slippage and chute blockages.

- Better housekeeping and safer work environments.

- Increased operational efficiency and compliance with environmental regulations.

What equipment is included in a typical Dust Suppression System?

- Low-pressure pumping systems (2-10 bar) for pre-wetting at dust generation points.

- High-pressure pumping systems (40+ bar) for fine mist to suppress airborne dust.

- Optimised spray and misting spray bars designed to suppress and eliminate dust.

- Surfactant and binder dosing systems to enhance dust control performance.

- Programmable logic controllers (PLCs) for remote monitoring and automation.

- Self-cleaning water filtration systems to ensure reliable operation.

How is the system installed?

- Fixed systems are installed at dust generation points such as conveyor transfer points and crushers.

- Fog cannons and misting units are mounted for strategic airborne dust control.

- Liquid additives are applied via water carts or spray systems.

Are the components modular or customisable?

Yes, Dust Suppression Systems are modular and scalable, meaning they can be customised for different sites and expanded as needed.

What are the power requirements for the system?

- Most systems use standard 415v industrial power supplies.

- Misting and spray systems require higher pressure pumps and electrical connections.

- For portable systems such as Fog Cannons, power generators are required

What is the expected operational lifespan of the equipment?

- With proper maintenance, Dust Suppression Systems components are designed for long-term operation, even in harsh environments.

- With customised designed systems, designed life of 5 to 10+ years can be specified, depending on customer needs.

Is the equipment compatible with existing dust control systems?

What does the commissioning process entail?

Commissioning involves:

- Installation and setup of Dust Suppression Systems components.

- Calibration of water flow, pressure, and chemical dosing.

- System testing to ensure optimal performance.

- Operator training on system operation and maintenance.

How long does the commissioning process take?

- Liquid systems are ready for use immediately after dilution and application.

- Fixed suppression systems typically take a few days to a couple of weeks to

- install and commission, depending on site complexity.

What are the prerequisites before commissioning?

For Fog Cannons systems:

- Site assessment and layout planning.

- Verification of power and water supply.

- Installation of foundational infrastructure if required.

- For fixed systems, the commissioning process would follow a typical project process.

Will the system require professional installation and commissioning?

What training is provided for commissioning and system operation?

Dust-A-Side Australia offers:

- On-site and remote training for operators.

- Guidelines on troubleshooting and maintenance.

- Comprehensive safety documentation.

How effective are these systems at controlling dust?

How is system performance monitored?

How often does the liquid additive need to be reapplied?

- Liquid binders last longer but require reapplication based on traffic, weather, and site conditions.

- Surfactants need to be dosed continuously into the system to ensure effective wetting of dust.

Do these systems have a positive impact toward sustainability?

Yes, Dust Suppression Systems:

- Minimise water usage with optimised application.

- Reduce chemical dependency through targeted suppression.

- Support sustainability by preventing dust migration off-site.

The liquid additives are also biodegradable

Are there any safety risks associated with using Dust Suppression Systems?

Dust Suppression Systems are safe when used correctly. We provide:

- Safety guidelines and operator training.

- Automated safety shutoff and trip systems.

What packaging and delivery options are available?

- Liquid suppressants are available in bulk or 1,000L Intermediate Bulk Containers (IBCs).

- Fixed suppression systems are custom-built and installed on-site.

What are the typical lead times for delivery?

- Liquid solutions are readily available for immediate dispatch.

- Mechanical systems have lead times that depend on customisation and installation needs.

Are bulk purchase or cost-saving options available?

Yes, we offer:

- Volume-based discounts for bulk orders.

- Service packages for cost-efficient long-term dust control.

Do you provide on-site application services?

Yes, Dust-A-Side Australia offers:

- Remote Supervision – Expert support for in-house teams.

- Managed Services – On-site supervisor overseeing applications.

- Full Service – Turnkey solutions with installation, equipment, and personnel.

What routine maintenance is required?

- Fixed systems require periodic servicing, sensor calibration, filter cleaning/replacement, and nozzle cleaning/replacement.

- Liquid binder treatments may need reapplication based on dust levels and weather conditions.

Are there service contracts available?

Yes, we offer custom maintenance plans to ensure ongoing system efficiency.

How do Dust Suppression Systems enhance operational efficiency?

- Improved equipment uptime.

- Reduced conveyor and chute blockages.

- Reduced equipment maintenance costs.

- Improved air quality and safety.

- Increased compliance with environmental regulations.

Are case studies or testimonials available?

Yes, Dust Suppression Systems has been successfully applied in mining and industrial operations, with documented case studies available.

Why should I choose Dust-A-Side Australia for my dust control needs?

Dust-A-Side Australia provides:

- Decades of industry experience in dust control.

- Custom-built solutions tailored to your site needs.

- Proven operational efficiencies and compliance support.

- Water savings of up to 95% and substantial cost reductions.

We go beyond products—we provide comprehensive dust suppression solutions that enhance efficiency, improve safety, and support sustainability.

Dust-A-Side Australia packages

Full Service

In addition to having a full time project supervisor on site, Dust-A-Side can also supply clients with required assets and personnel such as trucks, water carts, graders, suppression equipment and operators. Telemetry, consulting, project management and reporting are available with a Full Service package.

Managed Service

A full time project supervisor from Dust-A-Side will attend site to oversee the delivery and implementation of all dust control solutions, utilising the clients existing assets (e.g. water carts). The project supervisor will provide further support through telemetry, consulting, project management and reporting in order to help clients achieve the most efficient and cost effective outcomes possible

Remote Supervision

Provision of a fully self-contained storage and dosing package that requires no tie-in to existing site infrastructure, except a water source. The system includes a bulk storage tank, an unloading pump and a dosing pump, piping, and remote telemetry for monitoring usage and tank levels. It is maintained with monthly site visits, where technicians assess road conditions, manage product logistics, provide reporting on product and water usage, equipment utilisation and inspection, as well as operator training on product application and dust suppression techniques.

Supply Only

Binder products can be supplied in bulk or via intermediate bulk containers. Dust-A-Side will advise clients on how much of the product to apply and how often. Clients then apply the products using their own equipment.

Rental

Dust control equipment such as fog cannons can be rented as required and clients can manage the operation of the equipment.

Product range

We are proud to present an array of practical and innovative solutions.

No one knows more about dust suppression systems

With over 100 fully customised and purpose-built dust suppression systems in use globally, from conveyors to transfer stations, Dust-A-Side is an acknowledged leader in this field. All of these systems are triggered by remote control sensors and programmable logic controllers with fully automated, self-cleaning water filtration systems.

The pump modules are constructed from industrial grade components and are UL and CE rated for utmost performance and reliability.

Due to the harsh operating environment of heavy industry, Dust-A-Side Australia’s systems are fully enclosed, air conditioned and come complete with dust-proof components.

To reduce the use of water and enhance the system’s performance, binder products such as Aquatarp and Hydrotac, and surfactants like Hydrowet can be incorporated.

Hydrowet helps to break the surface tension of water particles, leading to smaller water droplets (between 5 and 10 microns) that attract dust particles to them, via agglomeration. This process is particularly effective when managing hydrophobic materials such as coal and other fine ores.

Backed by Experience

With decades of research and refinement to rely on, Dust-A-Side Australia has everything it takes to provide quantifiable results on every level.

Innovative Formulations

Our binder products include bitumen and polymer based emulsions, as well as organic binders, surfactant technologies and a range of blended products.

Committed to Sustainability

Our goal is to achieve Zero Harm and enhance environmental sustainability. Dust-A-Side binders are biodegradable and help to lower water consumption.

Continued Support

Our technical team will always be on hand to help ensure the success of your dust control strategy.

Contact us

For further information or advice about any of Dust-A-Side Australia’s proven products or services, simply fill out this form and we will get back to you.